The planning of resources and quality management, the use of tools on the shop floor, and scheduling people and equipment are all critical aspects of an advanced manufacturing operation. A company’s Enterprise Resource Planning system (ERP) manages company-wide resources, scheduling, and supply chain interruptions. To compete on a global scale, advanced manufacturing environments use ERP systems to orchestrate the many moving parts.

ERPs lack the granularity needed to put the right material in front of the right tool at the right time with a complex and dynamic production line. The use of ERPs is effective in the context of high-level, organizational roles within an organization. An additional layer must be integrated into the smart factory for it to be able to produce materials reliably, safely, and controllably as requested. In addition to manufacturing materials, a manufacturing layer should collect, store, and make accessible data about the actual manufacturing process, provide granular visibility into the manufacturing steps, and consistently enforce the same process requirements until explicitly altered. We refer to this additional layer as MES (Manufacturing Execution System).

Whatever the size or age of a company, manufacturers who are striving for success need a system that can keep up with the needs of today.

What is Manufacturing Execution Systems (MES)?

In manufacturing, MES (Manufacturing Execution Systems) automate and ensure quality and efficiency are systematically built into the manufacturing process. MES is a subset of enterprise resource planning (ERP) systems, executing the plans determined by the manufacturing resource planning (MRP) system. Compiling a bill of materials, managing resources, production schedule, preparing and dispatching production orders, and preparing work-in-progress reports (WIP) are all functions of MES programs.

These manufacturing execution systems connect multiple plants, sites, and vendors’ production information and integrate seamlessly with equipment, controls, and enterprise business applications. Production and processes across the enterprise can now be tracked, controlled, and optimized systematically.

MES (Manufacturing Execution System) from NetSuite provides the most up-to-date information from production facilities in real-time via the cloud. Besides traditional barcode scanners, NetSuite offers an interactive tablet app that provides feature rich interface and unparalleled feedback about what is happening within an employee’s work center and/or machine.

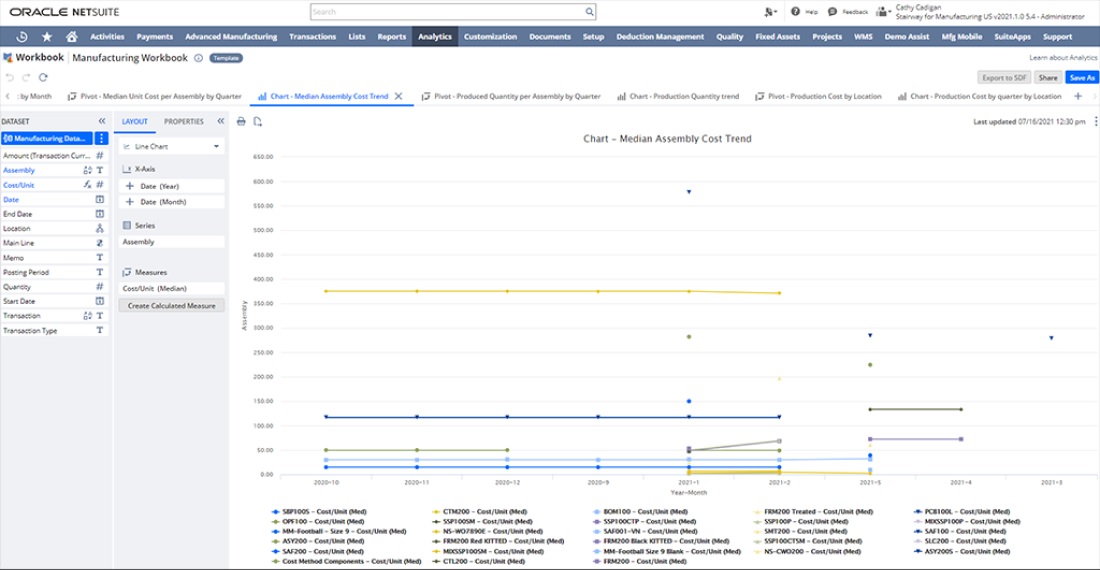

Image- Manufacturing workbook

All manufacturers, regardless of their size and industry, operate in the same business ecosystem and face the same challenges of today. The manufacturing industry is increasingly turning to NetSuite for their cloud needs.

Benefits of Manufacturing Execution Software

Manufacturing Execution Systems (MES) is a software solution that offer a number of long-term and short-term benefits, as well as strategic and tactical benefits, such as faster time-to-volume, improved yields, lower operating costs, and greater compliance.

Additional benefits of this software platform are as follows-

- Eliminate non-value add activities

- Proactively and systematically standardize and enforce processes across all sites

- Gain real-time visibility and control across the manufacturing supply chain

- Accelerate trace analysis, root cause diagnosis and issue resolution

- Lower cost of good quality

- Continuously improve product quality and new designs

- Make fact-based operational and strategic decisions

- Complete control over your manufacturing process

Introducing The NetSuite Manufacturing Execution system Features

The Advanced Manufacturing edition of NetSuite provides even more advanced features specific to the manufacturing sector, including:

- The human/machine interface (HMI)

- Bar Code Scanning

Human/Machine Interface (HMI)- Manufacturing mobile/tablet overview

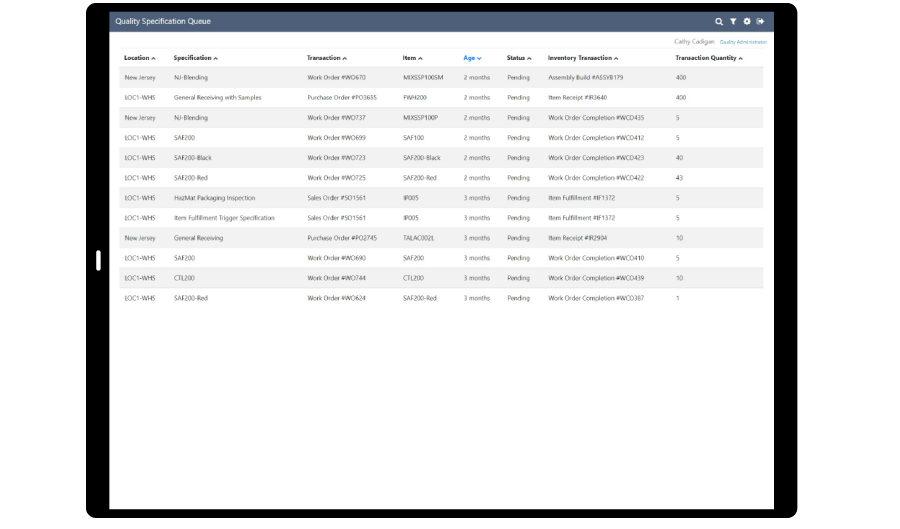

Image- HMI

This NetSuite Manufacturing Mobile SuiteApp lets production operators manage information on the shop floor using mobile scanners. With this mobile solution, production activities are streamlined, performance is improved, scalability is increased, customization is supported, and performance is scaled.

In order to complete transactions wirelessly in your warehouse, NetSuite Manufacturing Mobile uses the internet browser on your mobile device. NetSuite posts real-time updates to your NetSuite account as you complete transactions.

Advanced Manufacturing licenses are not required for this scanner solution. If you purchase NetSuite Manufacturing, you will automatically receive Manufacturing Mobile. Mobile bundles for SCM and Manufacturing may include assembly and work order licenses.

On the same scanner, manufacturing and WMS functions can be done simultaneously.

The Manufacturing Mobile Shop Floor Process

In NetSuite Manufacturing Mobile, shop floor workflow can be divided into four main activities:

- Staging of materials (not available at the moment)

- Consumption of components

- Finished good production

- Financial and inventory transaction reporting and updates

Manufacturing data collection and financial and inventory transaction reporting can be separated.

The production operator can still report to his production manager what has happened if using the Manufacturing Mobile workflow. In the Mobile SuiteApp, you can report a lot number that has not been recorded in NetSuite. During processing, data is checked for consistency and accuracy.

Workers on the shop floor can record events as they occur using tablets. Compared to NetSuite forms and handheld scanners, using tablets for data entry has the following benefits:

- The Advanced Manufacturing tablet interface presents a view of work to be completed, information about each operation, and data capture details.

- Shop floor travelers are no longer required.

- Tablet settings control display and filtering to better focus your work.

- Data entry is available in Real Time and Normal Mode.

In Real Time Mode, less data has to be entered by the operator. Date and time fields are interpreted in Real Time to streamline data entry.

Dates and times corresponding to operator actions are filled into relevant fields.

Work orders can be created using the NetSuite Advanced Manufacturing interface. There are the following features available in the tablet work queue:

- Available work orders appear in a list

- Assembly and Work Order details display in collapsible headers

- Color coded progress bar

- Smart component list

Using the Barcode Scanner to Enter Data

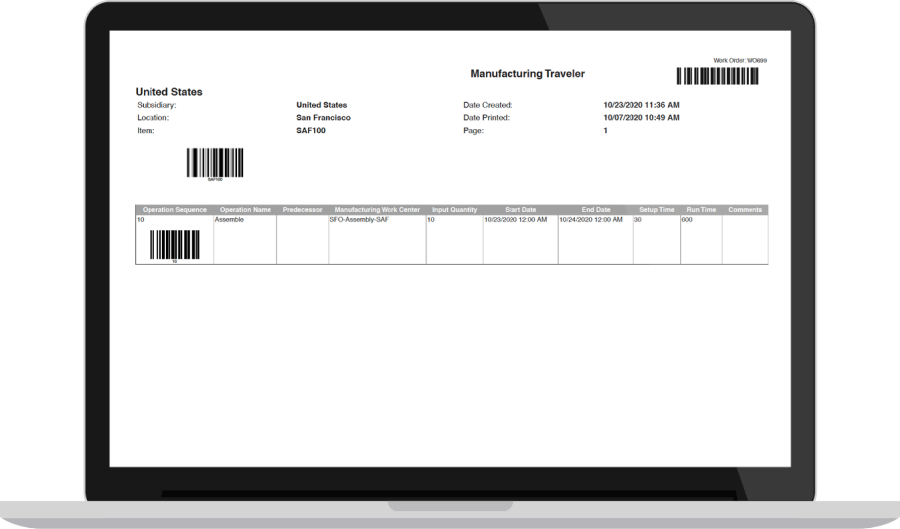

Image- Barcoding scanner

This barcoding application is native to NetSuite and can run on any platform. The app simplifies common transactions such as labor tracking, work order completions, material movements, PO receipts, and shipping transactions. Printed reports on the shop floor can all be accompanied by barcodes to ensure the data’s accuracy.

You can launch the scanner feature in the Advanced Manufacturing SuiteApp after you log in to NetSuite with the Data Scanner role.

You can collect production data by scanning barcodes on web forms based on following criteria-

- Production Tracking

- Recording Material Loss

- Recording Downtime

- Recording Labor tracking

Two-Factor Authentication (2FA)

Data Scanner roles are the only roles supported by NetSuite Advanced Manufacturing. Two-factor authentication accounts are not supported. Other user roles may experience two-factor authentication errors.

Set the Data Scanner role as the default status to launch the scanner outside NetSuite.

Conclusion

From big to small manufacturing business are turning to the Netsuite cloud. A cloud-based MES like NetSuite makes sure that the right people are in place at each step of the production process. In technical terms, MES connects and monitors machines and work centers on the factory floor. It gives you accurate, real time visibility to data for improved output. With Netsuite MES receive updates and use insights to make decisions that improve business operations.