Demand is the single most important factor for manufacturing and wholesale businesses.

The demand for these products impacts every aspect of their business, from their financial planning to their production planning, their supply chain management to their inventory management, shipping, and after-sales service.

What is Demand Planning & Forecasting Software?

Forecasting software allows companies to predict the upcoming demand for a product and plan their supply accordingly. A business demand forecasting software helps you avoid having slow-moving products that take up valuable inventory space or not having enough fast-moving products for future demand. It helps you to know what our upcoming demand is and avoid stock-outs or excess inventory. Forecasts, inventory management, and planning demand are used to accomplish this goal.

The goal of demand planning software solution is to ensure that you have the right amount of inventory on hand to fill orders without having overstock sitting idle on warehouse shelves.

How wonderful if factories, wholesalers, and other businesses could predict which of their products will be in demand, so they could prepare accordingly?

Can an ERP platform actually predict demand in advance so they can carve out plans in accordance with supply, if it understands their business so well?

No inventory will be wasted, production will be optimized, and all products will be delivered on time.

Due to NetSuite Demand Planning system, it’s not fiction anymore.

NetSuite Demand Planning: The Module Which Predicts The Actual Demand

Video Clip- NetSuite demand and supply planning

Due to its years of experience managing businesses overseas, including manufacturing and wholesale businesses, NetSuite has built Demand Planning into its suite of products.

Using NetSuite Demand Planning tools, manufacturers and distributors can predict the needed inventory based on inventory data and sales history.

A NetSuite Demand Planning module helps organizations purchase products at the right time and at the right place at the right price. Increasing this aspect alone can result in higher revenues, higher profits, and a greater return on investment.

In NetSuite, inventory management is facilitated by demand planning. Purchasing managers can easily analyze demand for their products based on historical data, forecasts and seasonal changes. As you plan for demand, NetSuite allows you to set different levels of stock and streamline your task flow.

Key Benefits of Demanding planning

- Utilize historical data or sales forecasts to calculate demand plans.

- By calculating supply plans, purchase or work orders can also be generated automatically.

- Display how future inventory levels could be influenced by expected sales and purchase orders.

- Visibility into item availability is available in real-time to let customers know when their orders will arrive.

Features of NetSuite demand planning

1. Demand Plan: Flexibility in Forecasting

Do you know what a Demand Plan is?

Demand plans predict demand for items based on past demand or projected demand. Using the page Calculate Demand Plan, a demand plan can be created automatically. The goal of this page is to assess previous demand for items and estimate the upcoming demand.

One of the methods NetSuite provides for forecasting demand for items includes:

-

- Identify a time frame for analyzing an item’s historical sales data and forecasting future sales based on similar trends.

- To forecast future sales, use current demand, such as opportunities, quotes, and sales orders. Calculated forecasts are not used in this method.

- Forecasting data is used by NetSuite to estimate demand over a designated time period in the future and suggest an order plan accordingly.

NetSuite allows you to determine your demand plan based on historical or forecast data for a particular period of time. The accurate forecast data is used to determine seasonal fluctuations in inventory levels. Additionally, preferred stock levels can be set on a company-level or on an item-by-item basis when generating the demand plan. Projections are calculated on a per-location basis so that demand can be accurately predicted in a given area. When you have generated your demand plan, each period’s inventory needs can be reviewed and modified.

4 Planning Models Under NetSuite Demand Planning

Businesses can plan their next moves based on sales forecasts, historical sales data, inventory positions, and more with NetSuite’s Demand Planning module.

The 4 planning models are as follows:

a. Linear Regression Model

Based on the previous demand metrics, the businesses are able to build future inventory requirements using the ordinary least-square regression method. According to this model, the unknown parameters are estimated using linear regression.

b. Moving Average Model

A company can determine the amount of inventory it needs for a product by using the moving average of historical demand. The overall average is then used to project all future stock levels.

It is a dynamic planning method for fast-moving consumer products.

c. Seasonal Average Model

Based on seasonal trends, as well as historical data related to a product, businesses can make predictions about demand for a product in the future. These predictions help manufacturers, wholesalers, and retailers stock up on seasonal items so that their distribution and sales will be seamless.

These models are particularly useful if you sell products that are in high demand during holidays or specific seasons, like raincoats and umbrellas during the monsoon season, or woolen clothes and jackets in winter. It can be a game changer to use these types of prediction models.

d. Sales Forecast Model

Businesses can stock up their inventories using forward-looking accurate sales forecasts under this model. Sales forecast data includes opportunities, estimates, among others.

Similarly, demand planning brings additional advantage to your sales operations and will help you achieve success.

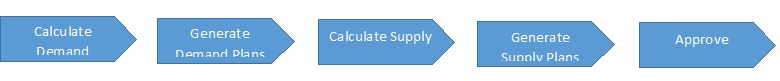

2. Demand Planning process

Demand planning is a business process for identifying and managing customer demands for products and services. Forecasting a customer’s demand entails applying the most appropriate statistical models. During a demand planning process, a company generates a sales plan that initiates a service-planning process, production planning, inventory planning, and revenue planning.

Image- Demand Planning process

3. Supply Plan : Streamlined Replenishment planning

A supply plan is what?

An item’s supply plan specifies the schedule for purchasing or manufacturing additional supplies. Based on lead times and expected demand, it recommends purchase orders for augmenting item supply. Lead times are incorporated into a supply plan, so you can place orders in time to receive the items when the demand increases.

From the item record, purchase orders are generated from supply plans using the preferred vendor. Supply calculations take safety stock level settings into account. Throughout a multi-tier assembly, all levels of the entire supply chain are considered. Plan all sub-components of a build and purchase raw materials from NetSuite. The Calculate Supply Plan page can be used to generate a supply plan from a demand plan.

Maintaining an optimal level of inventory allows you to keep your demand plans and supply plans up to date. It also helps distributors, manufacturers and retailers handle processes for demand forecasting and inventory replenishment planning.

A supply plan can be created for specific items after a demand plan is created. Depending on the parameters you set in the item record, such as Reorder point and lead time, NetSuite Demand Planning suggests purchase orders or work orders.

A purchase order that is generated uses the vendor from the item record and a work order is generated for sub-components for all levels of the assembly and a purchase order is generated for the raw materials, so even the most complex demand planning environment is easily accommodated. Furthermore, the supply plan allows you to choose which items to automatically calculate ordering requirements, which provides flexibility when different methods are required.

4. Gross Requirement Inquiry: Modeling In Levels

With Demand Planning in NetSuite, you can also represent how expected sales and purchases will affect a company’s future inventory levels through an enquiry. In order to maintain a positive impact on your business, you need this feature.

Compared to other inventory management software, NetSuite provides the best-in-class inventory management functionality because it maintains the right amount of inventory to effectively meet anticipated demand and maintains the delicate balance of “right” inventory. Having only adequate inventory eliminates the risk of putting too much or too little capital into inventory, and prevents failed sales or customer dissatisfaction because stock isn’t available.

A report displays all changes in stock level for selected items retrieved from your account. According to the enquiry results, we know when an item was received from the supplier, shipping date, date of Order, type of action affected the level of inventory and quantity.

NetSuite makes it very easy to generate reports for demand planning.

5. Multi Location inventory

In addition to location tracking and OneWorld support, NetSuite inventory management offers a multi-location inventory feature. It is integrated with UPS® & FedEx® for easy shipment and provides flexible pick, pack, and ship process workflows. Additionally, it offers a return management facility as well as support for warranties and repairs.

In combination with the Advanced Multi-Location Inventory, the users can setup different UPS® and FedEx® accounts for each location. Thus, the multi-location feature generates real-time rates and correct labels for each warehouse. Orders can be given a fulfillment location when they are created filled.

It includes advanced inventory management tools across multiple locations, as well as superior customer service levels for increased customer satisfaction.

The following are some other features that make Advance Multi-Location Inventory stand out:

- Bin Management

- Demand-based Inventory Replenishment

- Accurate Order Promising & Inventory Commitment

- Order Management with Advanced Shipping

- Integrated UPS® & FedEx® with Tracking

- Returns Management in One System

6. Allocation Exception Management

With automated order exception handling, merchants can scale their businesses with fixed headcount. Once NetSuite has attempted to fulfill exception orders, it informs the fulfillment manager or CSR that the order was not fulfilled. A flag is automatically raised when inventory discrepancies arise.

To ensure that high priority sales orders arrive on time and complete, you can review all supply sources as well as order allocations in response to supply shortages and VIP customers. To minimize the effect on all orders, it provides intelligent supply reallocation recommendations that make use of resources from multiple unallocated orders and fulfill priority orders first to maximize functionality.

By generating reallocation recommendations, the system reduces the amount of time it takes to find, review, and execute reallocations. Once you accept a recommendation, the system re-aligns the supplies to the affected orders.

It is possible to generate a new set of allocation recommendations if you do not like the generated recommendations.

If you still don’t have a solution, you can go back and re-examine reallocation scenarios. As soon as you approve an allocation, you are returned to the order.

7. Item Setup

The planning process begins with defining the parameters that affect each item. Items are subject to Inventory Management settings unless they are overridden in the location sublist. It indicates the item is available for demand planning, establishes an alternate source item (if it doesn’t have a sales history), then determines if it belongs to a Distribution Network or Category. This sublist contains additional planning parameters that either affect how orders are evaluated or how demand is estimated.

These settings include-

- Safety Stock

- Let Sizing Method

- Fixed Lot Size

- Supply Planning Periods

- Supply type

- Demand source

- Forward and backward consumption days

- Demand and planning time fences

- Reschedule in/out days

8. System Setup

The Netsuite demand planning and distribution resource planning modules must be enabled in your account to be available to users. There are also several other settings that affect how the system behaves.

9. Order Execution

It is easier for users to create order, transfer orders, and work orders by implementing the planning process, and they will be notified in various ways when something needs to be done.

- Reminders

- Email alerts

- Saved searches

- Scheduled reports

Order items and mass create work orders can be created by checking the boxes next to the orders you wish to create and clicking the button.

The Bottom Line

Demand and supply planning is a powerful NetSuite feature that helps business grow by allowing them to make faster and better decisions by having all of this information within NetSuite itself. NetSuite gives you an edge in the marketplace by empowering your intelligence.

The practice of demand planning is crucial for business growth. NetSuite’s ability to manage demand and supply is one of its many features. Advanced Demand Planning in NetSuite, businesses can use this module to determine the time horizon during which inventory must be in stock to ensure timely delivery to customers.

Artificial intelligence (AI) and machine learning are the future of demand planning because they help to process large amounts of data, and many times this data is un-identifiable to a human being.