The Warehouse Management System: What Is It?

Video- Netsuite Warehouse Management

WMS software automates and coordinates the many moving parts of the warehouse including staff, equipment, inventory levels, orders, and processes.

The warehouse management system makes it possible to track every aspect of day to day warehouse operations in real-time, including the location of every item to the number of employees on the packing floor. From workforce scheduling to picking and shipping orders, it helps manage and optimize warehouse processes.

By automating these processes, companies can save time and money, as entire supply chain costs are a major component of their operations.

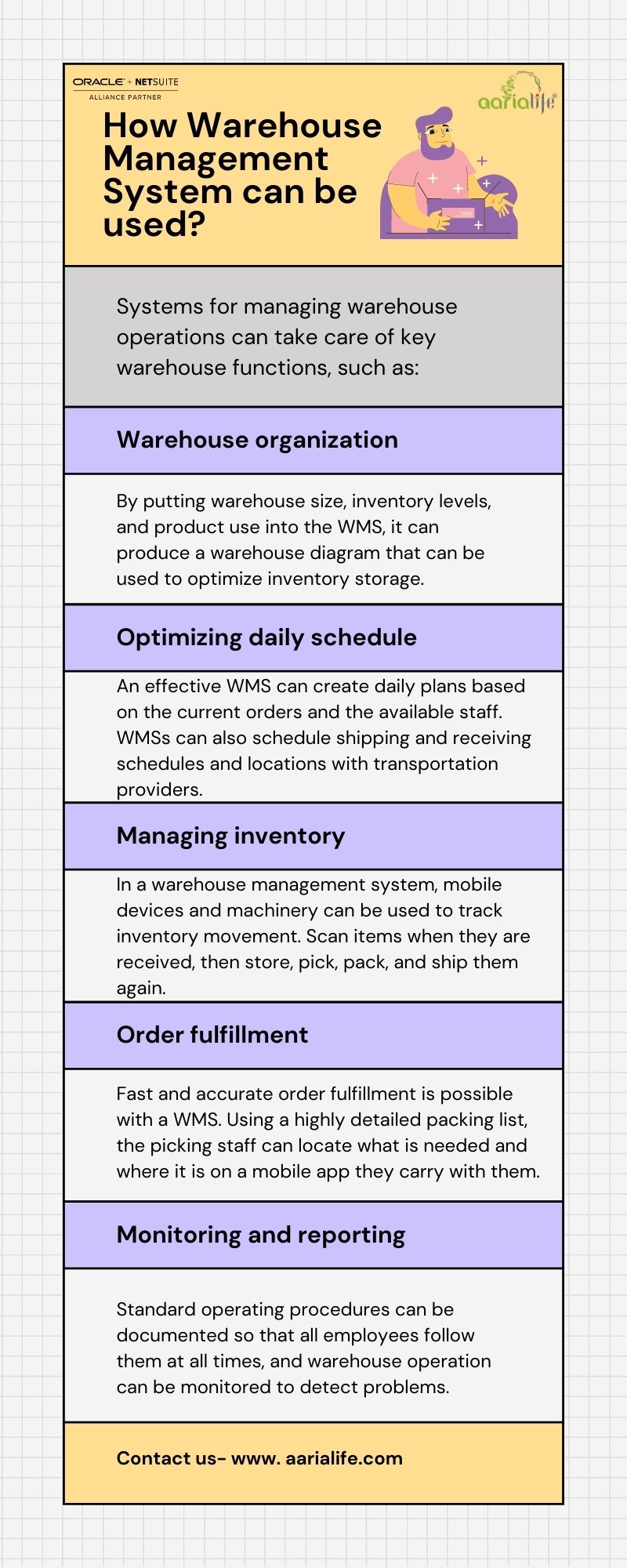

How Do You Use a Warehouse Management System?

NetSuite Warehouse Management is what?

In NetSuite Warehouse Management System (WMS), has an additional functionality to streamline leading practices, including mobile/ RF bar code scanning handheld devices and defined strategies for picks and put-away and picking, task management, authorization receipt for return orders, and cycle counting, which are used to optimize warehouse operations. If you rely on spreadsheets – or worse, pen and paper – to keep track of hundreds or even thousands of SKUs, warehouse management can quickly become a manual, chaotic and inefficient process. By eliminating manual processes, NetSuite Warehouse Management Solution allows you to minimize handling costs, run your warehouse more efficiently, and consistently meet customer expectations.

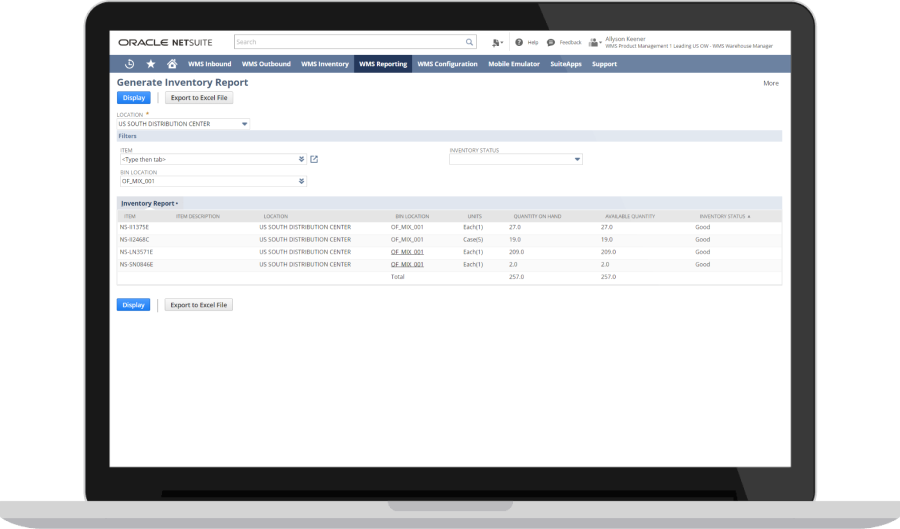

Functionality of NetSuite Warehouse Management

WMS elements such as hand-held barcode scanning, cycle count plans, and integration with shipping systems streamline warehouse operations using industry-leading best practices.

-

Inbound Logistics

Image- Inbound logistics

Companies can manage their inbound inventory tracking efficiently with NetSuite’s inbound logistics capabilities. In NetSuite, dashboards help manage multiple tasks, from managing pending orders to scheduling specific receipt dates. Perform vendor quality checks when products have been received to ensure they meet your needs. Standardize put-away processes with predefined guidelines.

a. Purchase Order Receiving

Receive outstanding purchase orders, transfer orders, and authorize returns as soon as they arrive at your warehouse.

i. Partial receipt- Compare received items to an open order when a shipment arrives to ensure that all items have been received. Using a receipt to specify exactly what you have received, you will be able to track which items are currently in stock and which are still on their way. It is also possible to print labels directly from a purchase order or receipt.

ii. Track overdue and expected orders- It highlights in color the orders more than 24 hours past their due date or expected date, and allows users to contact primary contacts directly by phone or email.

iii. Receiving transfer orders- When items are transferred between locations and received at a warehouse, the transfer order must be marked as received by entering an item receipt. When a transfer order is received into inventory, the quantities received are added to the Quantity on Hand at the receiving location.

iv. Receive customer returns- When a customer returns an item to your business, match the shipment to the corresponding return authorization number. Match item receipts with the open authorized returns. Identifying authorized returned items as received when they arrive updates item and order information, including inventory on hand and return status.

v. Landed cost management – As items are received, apply landed costs appropriately. To track all expenses incurred when purchasing, you can create different landed cost categories. A few examples are:

- Shipping charges

- Freight costs

- Import fees

- Customs and duty

- Taxes

- Insurance

- Handling charges

b. Container Tracking

The tracking for shipments is performed as they depart from the supplier, go to the destination, then to the buyer.

i. Inbound shipment record- Inbound shipment management records gather all open purchase orders in one place from multiple vendors, allowing for simplified status updates until receipt. By selecting a container, users can view all items loaded into it, filtering by vendor and PO number. The link between a PO line and a container is established with this process.

ii. Status updates- As a container makes its way to your door, keep your records up-to-date. Container transit times can be months or even years, and the items inside them may be required for multiple commitments – sales orders, further transportation, assemblies and more – so it is essential to be able to track container status on a timely basis. Regularly updating the inbound shipment status field keeps everyone informed.

iii. Container receiving- In order to ensure a container arrives unloaded and received quickly, companies must understand exactly what’s in it. With just a single click, a container can receive its entire contents upon reaching its destination. It eliminates manual processes associated with receiving. As well as making partial receipts, that’s also possible.

iv. Landed cost management- Landed cost calculation for items in containers is a crucial part of the process. Depending on the cost of the costs, they can either be applied over the entire shipment, for example with brokerage fees, or to specific items, like customs duties.

c. Quality Assurance

A quality assurance process ensures your warehouse items will be as expected when they arrive. Set pass/fail criteria for inbound inspections, set acceptable parameters for failed items and develop a process for handling failed items.

2. Order Fulfillment

Image- Order fulfillment

Order fulfillment in NetSuite ensures quick and accurate delivery of customer orders. Streamlining and standardizing fulfillment processes increases efficiency and decreases errors. In accordance with company policy, users are guided through the fulfillment process using pick-and-pack logic and strategies. The way orders are processed can be further customized by setting up a wave release strategy, choosing wave status, and picking single or multiple types.

a. Pick, Pack & Ship

The pick, pack, and ship functionality in NetSuite provides a simple, streamlined process for fulfilling any order. Plan your pick-and-pack strategy so that you can dictate exactly when and how your inventory should be used to fill outbound orders. In addition, the NetSuite WMS mobile app guides users to expeditiously fulfill orders, ensuring optimal inventory utilization and avoiding costly mispicks by using the app.

i. Wave release- Warehouse managers can identify where to release orders for picking based on any criteria – customer, expected shipping date, item/zone, and shipping method – by using wave release policies and templates. It is possible for companies to filter the orders they want to include in a wave and schedule their release to the warehouse. A mobile application can be used to release orders.

ii. Defined pick strategies- Using predefined pick-and-pack strategies, companies can dictate how and when inventory should be utilized to fulfill outbound orders, thus ensuring optimal utilization. NetSuite can identify the recommended bin location based on concepts such as first-expired-first-out (FEFO), serial number tracking, pick to clean, pick to fill, or primary bin location.

iii. Multi order picking- NetSuite picks orders simultaneously rather than chronologically, so staff can pick like items from all orders simultaneously rather than chronologically. This reduces the number of back-and-forth trips required to pick up the same items.

iv. Pack station- Pack Station increases packing and shipping efficiencies by identifying picked items that have the same shipping routes so that they can be packed together in the same shipment. By using your kiosk device, you can print customizable carton labels, pallet labels, bills of lading and packing lists, as well as capture weights from a weighing scale.

b. Cross-Subsidiary Fulfillment

Companies can easily define which subsidiaries and locations can trade with each other and under what conditions using NetSuite cross-subsidiary fulfillment. As a result, inventory is used more efficiently across various subsidiaries. Assigning individual lines to multiple subsidiaries for fulfillment and shipment lowers shipping costs and minimizes the need for intercompany transfers and drop-shipping.

i. Location Assignment- Companies can automatically assign subsidiary locations to sales order lines based on predefined rules that take into account location. It is possible to select individual subsidiaries, all subsidiaries, and individual locations from which to fulfill.

ii. Inventory relationships- Organizations need less stock overall and have lower overhead costs when inventory is optimized across all locations, selling channels, and subsidiaries. Establish fulfillment policies that automatically select the optimal fulfillment locations. It is crucial to keep track of global inventory relationships to ensure that products are assigned to the closest location, reducing shipping costs.

iii. Cross charge transactions- With cross-charge transactions, cross-subsidiary fulfillments can be handled in a complex intercompany manner. Cross charges are automatically created for multi-subsidiary transactions as part of the closing process for the accounting period.

iv. Return process- Making the return process as seamless as possible is key to increasing customer loyalty. Make the process simple by accepting returns from anywhere. An return material authorization RMA can be processed for the return of items to one or more locations, across any branch. Customers will be pleased and inventory will be replenished immediately.

c. Carrier Integration

Customers receive their orders on time because we integrate with many of the world’s leading carriers, including UPS, FedEx, and USPS.

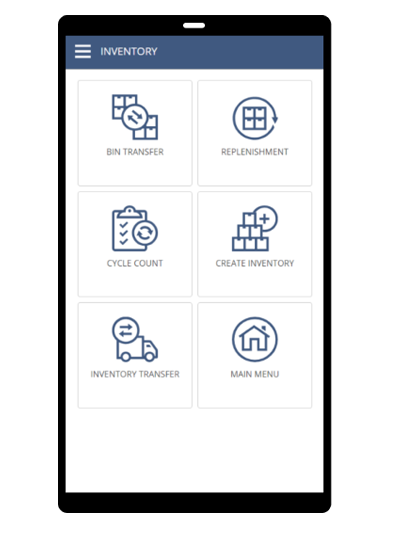

3. Mobile Warehouse Management

Image- Mobile warehouse management

With NetSuite mobile warehouse management, users can perform all of their day-to-day warehouse management tasks from a mobile device, including receiving, putting away, picking, and packing. Access real-time warehouse information, inventory, and orders by allowing employees to leave the office and go on the floor. The NetSuite WMS app improves efficiency, minimizes human error, and ensures accurate data and real-time visibility.

a. Receiving

A best practice for increasing data integrity is to force scan inventory items when they are received. In order for an item to enter inventory, it has to be scanned and entered by force. As items are received, assign lot and serial numbers, bin locations, and inventory status automatically.

b. Picking, Packing and Shipping

By validating items against the originating transaction, the mobile app and force scan for picking and packing of orders prevent costly mis-picks and ensure accurate data capture. Companies can then keep track of all sales.

c. Inventory Visibility

As items are scanned, the inventory is tracked updated immediately and systemically. Once stock is accepted into inventory, it can be used for subsequent processes, such as quality assurance, outbound commitment or fulfillment. The scanning of work orders, associated bills of material, and inventory moves between warehouses provides visibility in real time.

d. Cycle & Physical Counting

Conducting cycle counts on a mobile device reduces manual errors and expedites the process. It requires users to scan at every step in order to verify they are in the right place during the count. Scanning also automatically update the count record. There is no need to write data down after the fact and manually enter it on a computer.

4. Bin Management

Image- Bin management

With NetSuite WMS, inventory can be managed using bins. In addition, NetSuite enables locations without bins, such as retail stores and small warehouses, to benefit from mobile picking without the overhead of managing bins. Perform order processing and inventory management operation tasks on a mobile device, define stock locations and associate them with items, and view stock locations assigned to goods being processed.

What Kind of Warehouse Management System is Best?

WMS applications are available for a variety of industries and companies of all sizes. In order to determine how well each product meets your requirements, it is important to carefully research choices based on the industry and each company’s unique business needs.

The ideal WMS should provide real-time view and insights into your business operations, be intuitive and easy to learn, continue to be flexible as the business grows and adapts to changing market conditions, and be easily integrated with other business applications.

As companies become more efficient and accurate, they turn to WMS to meet their delivery needs without incurring unsustainable costs. The WMS platform can be integrated into an ERP solution or can be delivered as a standalone product.